Waste treatment

Waalwijk, Netherlands

Topics addressed in this section:

> Waste prevention and reduction: reduce, reuse, and recycle

> Wastewater treatment

Wastewater treatment

Most of our sites have their own wastewater treatment facilities. At our other locations, wastewater is collected and treated by a third party, before being reported and processed as hazardous waste. A new water treatment facility built at Stahl's Waalwijk site in the Netherlands became fully operational in September 2022.

In 2022, the total wastewater sent by Stahl for external treatment decreased by 11% compared with 2021.

Back to overview

Scroll

down

At Stahl, we aim to minimize our impact on the environment and the communities in which we operate by preventing pollution through a combination of different waste minimization, reuse, recovery, and recycling strategies. Our aim is to prevent waste from being generated in the first place and to find useful applications for any remaining waste materials.

The policy follows what is known as the waste hierarchy, with a focus on the “three Rs”: reduce, reuse, and recycle. The hierarchy helps us to prioritize the actions we take to manage our waste, both before and after it is created.

First and foremost, our policy aims to prevent or reduce waste at source, by reusing products and materials before they become waste, by recycling waste materials into new materials and objects (or recovering them and converting them into energy), or by substituting other materials that would otherwise have been used to fulfill a particular function. Where these activities are not possible, waste must be disposed of in an environmentally sound manner. Sending used materials to landfill is a last resort.

Our Global Waste Management Policy aims to:

Implement effective waste management practices, enabling us to identify the most efficient methods to minimize waste and maximize the reuse or recycling of used material;

Manage the entire process to ensure full compliance with best practices; and

Enable Stahl’s local teams to understand their responsibilities under environmental law and how to maintain compliance with all relevant regulations and standards.

Continuous improvement

Preventing pollution

Complying with legal and other requirements

Setting environmental objectives and targets

In 2022, Stahl introduced its new Global Waste Management Policy, based on the principles of the Circular Economy and the ISO 14001 standard for environmental management. The policy covers four central topics:

Managing waste

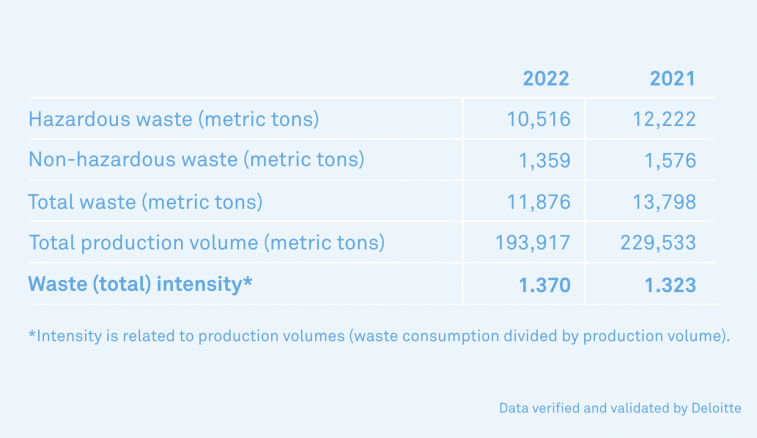

Stahl focuses on waste prevention, waste reduction, and recycling, but the manufacture of our products still generates hazardous and non-hazardous waste. Some of the waste we produce is categorized as hazardous. This includes waste from chemical-related sources, such as our products, raw materials, process equipment (such as sludge from wastewater treatment), laboratories, and used packaging. The rest is classified as non-hazardous (non-chemical) waste. This includes glass, paper, wood, plastic, and household and demolition waste. In 2022, the amount of waste Stahl produced decreased by 14% compared with 2021. This was linked to a reduction in our production volumes. Our waste intensity (metric tons of waste produced per metric ton of product manufactured) remains relatively stable (1.37 in 2022 vs. 1.32 in 2021).

Data verified and validated by Deloitte

Data verified and validated by Deloitte

*Waalwijk (Netherlands), Calhoun (USA), and Toluca (Mexico).

Wastewater sent for external treatment

(metric tons)*

2022

2021

13,558

15,245

Back

to top

Back to overview

Wastewater treatment

Most of our sites have their own wastewater treatment facilities. At our other locations, wastewater is collected and treated by a third party, before being reported and processed as hazardous waste. A new water treatment facility built at Stahl's Waalwijk site in the Netherlands became fully operational in September 2022.

In 2022, the total wastewater sent by Stahl for external treatment decreased by 11% compared with 2021.

Back

to top

At Stahl, we aim to minimize our impact on the environment and the communities in which we operate by preventing pollution through a combination of different waste minimization, reuse, recovery, and recycling strategies. Our aim is to prevent waste from being generated in the first place and to find useful applications for any remaining waste materials.

The policy follows what is known as the waste hierarchy, with a focus on the “three Rs”: reduce, reuse, and recycle. The hierarchy helps us to prioritize the actions we take to manage our waste, both before and after it is created.

First and foremost, our policy aims to prevent or reduce waste at source, by reusing products and materials before they become waste, by recycling waste materials into new materials and objects (or recovering them and converting them into energy), or by substituting other materials that would otherwise have been used to fulfill a particular function. Where these activities are not possible, waste must be disposed of in an environmentally sound manner. Sending used materials to landfill is a last resort.

Our Global Waste Management Policy aims to:

Implement effective waste management practices, enabling us to identify the most efficient methods to minimize waste and maximize the reuse or recycling of used material;

Manage the entire process to ensure full compliance with best practices; and

Enable Stahl’s local teams to understand their responsibilities under environmental law and how to maintain compliance with all relevant regulations and standards.

Managing waste

Stahl focuses on waste prevention, waste reduction, and recycling, but the manufacture of our products still generates hazardous and non-hazardous waste. Some of the waste we produce is categorized as hazardous. This includes waste from chemical-related sources, such as our products, raw materials, process equipment (such as sludge from wastewater treatment), laboratories, and used packaging. The rest is classified as non-hazardous (non-chemical) waste. This includes glass, paper, wood, plastic, and household and demolition waste. In 2022, the amount of waste Stahl produced decreased by 14% compared with 2021. This was linked to a reduction in our production volumes. Our waste intensity (metric tons of waste produced per metric ton of product manufactured) remains relatively stable (1.37 in 2022 vs. 1.32 in 2021).

Continuous improvement

Preventing pollution

Complying with legal and other requirements

Setting environmental objectives and targets

In 2022, Stahl introduced its new Global Waste Management Policy, based on the principles of the Circular Economy and the ISO 14001 standard for environmental management. The policy covers four central topics: