2022 saw the extension of Stahl's on-site renewable energy program. With the addition of a new ground-mounted solar plant at our manufacturing facility in India in October, Stahl is on track to meet its 2030 target of six sites being powered by their own purpose-built renewable energy sources.

The Kanchipuram-based site is the third Stahl plant, after Brazil and Mexico, to meet part of its energy needs with renewable energy generated on site. This was one of our 2023 targets in Stahl’s ESG Roadmap to 2030. With an installed capacity of 840KWp, the solar plant at the Kanchipuram site will provide sufficient power to support the plant’s needs during the generation period, while surplus power will be exported to the grid under the net metering model. In the future, it is estimated that 25-30% of Kanchipuram’s power needs will be met by the solar plant.

In 2022, Stahl Italy and Stahl Mexico also completed the installation of solar water heaters. This has significantly reduced the use of fossil fuels to heat water for production and hygiene purposes.

Notes

2022 Emissions (tCO2e)

Direct CO2 removals

from bioenergy (S1)

4,575

4,611

CO2 removals due to the biological source's

sequestration during its life

CO2 emissions emitted from the combustion of the biological source for bioenergy PLUS the land use change emissions as a result

Direct CO2 emissions

from bioenergy (S1)

Out of scope (CO2 only)

• Ensure that all new product development uses available low-impact raw materials.

• Establish raw material working groups, per material or per category, in which low- carbon alternatives are introduced to replace higher-carbon solutions.

• Measure indirect raw material C02 emissions based on LCA data from suppliers and the ecoinvent/SimaPro database.

• Focus on the top raw material categories, and top individual products, according to \ their GHG impact (i.e., purchased volume x emission factor).

Data verified and validated by Deloitte

How we plan to get there

• Replace fossil-based raw materials with lower-carbon alternatives, like renewable =. (e.g., biobased and recycled) feedstocks.

• Ensure that all new product development uses available low-impact raw materials.

• Establish raw material working groups, per material or per category, in which low- carbon alternatives are introduced to replace higher-carbon solutions.

• Measure indirect raw material C02 emissions based on LCA data from suppliers and the ecoinvent/SimaPro database.

• Focus on the top raw material categories, and top individual products, according to \ their GHG impact (i.e., purchased volume x emission factor).

Using less energy (Scopes 1 and 2) overall and using energy from renewable sources are both key to achieving our emissions reduction targets. We plan to install more self-generating electricity (solar power) at selected manufacturing sites, and we are continuously investing in energy-saving equipment.

To reduce our Scope 3 (indirect) emissions, we plan to do the following:

SBTi validation is pending (final stage)

Taking action on climate change

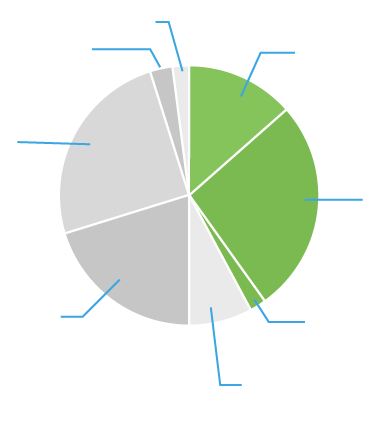

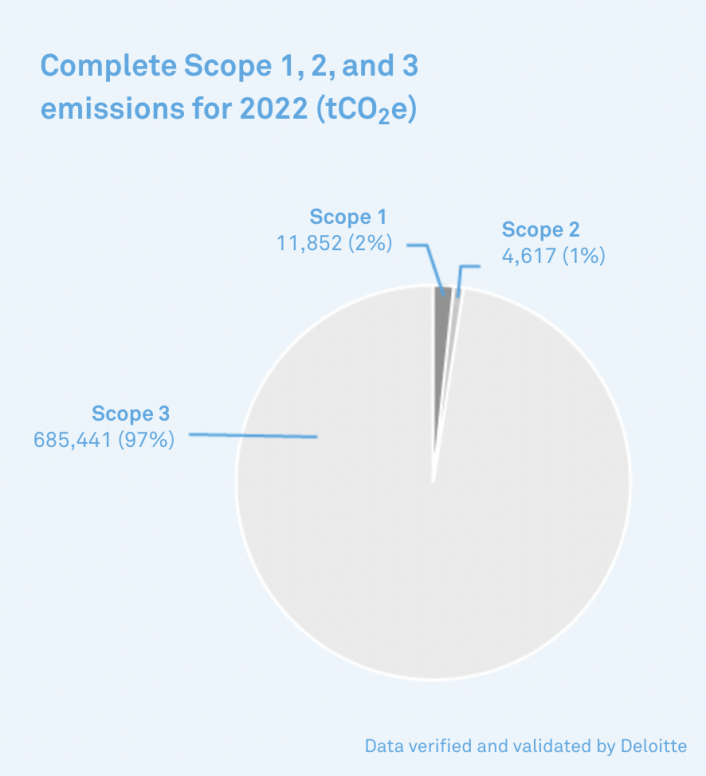

Complete Scope 1, 2, and 3

emissions for 2022 (tCO2e)

Scope 2

4,617 (1%)

Scope 3

685,441 (97%)

Scope 1

11,852 (2%)

Furnace oil

(TJ) – 20%

Steam (TJ) 2%

Grey mix electricity

(TJ) – 8%

Self-generated renewable electricity

(TJ) - 2%

Purchased renewable electricity

(TJ) - 26%

Renewable

briquettes (TJ) 14%

High-speed diesel – 3%

Gas

(TJ) – 25%

Data verified and validated by Deloitte

Energy intensity (TJ/ton)*

Total production volume - in tons

Share of renewable energy

2021

42%

38%

193,917

229,533

0.00161

0.00157

359

312

2022

Energy - in terajoules (TJ)

Energy consumption

*Intensity is related to production volumes, calculated by dividing energy consumption by production volume.

Energy sources

As we build on this momentum, we have a key milestone firmly in our sights. 2030 will mark the 100th anniversary of Stahl. It is also the end point of our ESG Roadmap to 2030, by which time we expect to have achieved our mid-term ESG targets. More importantly, by the end of this decade, I expect to see the wider chemicals industry making more significant progress toward de-fossilization than in the previous 30 years, with Stahl acting as a driving force in our markets.

Collaboration will be key. By working together – as one value chain – I believe the chemical industry can be part of the solution for mitigating climate change, reversing the global warming trend, and progressively reducing biodiversity loss.

This section of our 2022 ESG Report follows our climate change ambitions and our recent efforts to reduce the environmental impact of Stahl and its value chain partners.

Achieving our GHG targets will be challenging, since many of the activities in the value chain take place upstream, beyond our direct influence. However, we have built the foundations needed to help us get there. As a founding member of the Renewable Carbon Initiative (RCI), we play a key role in supporting the de-fossilization of the chemicals value chain and its transition to renewable feedstocks. We are investing significant resources in measuring the footprint of our raw materials and products using Life Cycle Assessment (LCA) methodology. We are also working to secure relevant supply chain certifications, such as RedCert² and ISCC PLUS.

Reducing our impact, together

Addressing climate change is the number one priority for all stakeholders across the chemicals sector. The industry is estimated to be responsible for roughly 7% of global GHG emissions, and its relative contribution is likely to increase as the energy sector steadily decarbonizes.

Stahl has achieved significant reductions in GHG emissions since 2015 (37% absolute emission reductions in 2020 in Scope 1 and 2) when the Paris Agreement was signed. In 2022, we submitted an emissions reduction target to the Science Based Targets initiative (SBTi).

Michael Costello

Group Director ESG at Stahl

Topics addressed in this section:

> GHG emissions targets and reduction plan

> Climate resilience and adaptation

> Greenhouse gas (GHG) emissions

> Energy use

> Case study: taking action on climate change

Back to overview

Scroll

down

Energy and emissions

Stahl’s energy consumption comes primarily from its production processes (whereby chemical reactions are used to produce specialty products). We continue to invest in cleaner and renewable energy sources and to further reduce our energy consumption. The largest potential improvement area for GHG emission reduction is linked to the purchase of raw materials. In 2022, Stahl’s GHG emission reduction targets were submitted to the Science Based Targets initiative (SBTi). Science-based targets provide a clearly defined pathway for companies to reduce GHG emissions, helping prevent the worst impacts of climate change to enable future-proof business growth. Targets are considered to be science-based if they are in line with the scientific consensus on the level of action required to meet the goals of the Paris Agreement: limiting global warming to 1.5°C above pre-industrial levels.

Our SBTi target (pending validation) is to reduce absolute Scope 1 and Scope 2 GHG emissions by 42% over the next ten years (2030 target year versus 2021 base year). We will do this by reducing our energy consumption and continuing our transition to renewable energy sources. Stahl’s European sites already purchase 100% of their electricity from renewable sources, and we have installed solar panels at 3 sites: Brazil (2018), India (2022), and Mexico (2022).

Scope 1 absolute emissions in 2022 dropped by 15% (11,852 tCO2e versus 13,898 tCO2e in 2021), mainly because of energy efficiencies and lower production volumes.

Scope 2 absolute emissions dropped by 24% (4,617 tCO2e versus 6,101 tCO2e in 2021), mainly as a result of our investment in solar panels.

ESG roadmap to 2030

2030 goal: 6 sites using on-site renewable sources

(minimum 20% of total energy usage)

2022 progress (on target): solar panels installed at 3 sites

Greenhouse gas emissions at Stahl

Data verified and validated by Deloitte

*Intensity is related to production volumes (CO2 emissions / production volume). Stahl’s CO2 intensity remained stable (0.0849 in 2022 versus 0.0871 in 2021).

Scope 1: fuel combustion at our sites (gas, oil, diesel and renewable briquettes). No coal is used.

Scope 2: purchased electricity, heat and steam. GHG emissions are reported in CO2e. Carbon dioxide equivalent (CO2e) emissions represent emissions of all greenhouse gases (CO2, CH4, N2O, HFCs, PFCs, and SF6), aggregated and converted to units of CO2e using global warming potential (GWP) values.

Scopes 1 and 2 include emissions from all 11 manufacturing sites where Stahl products are produced. Other locations, such as offices, labs, and home offices, were excluded from the 2022 calculations. The emissions from other non-manufacturing sites are estimated as part of Stahl's SBTi submission and account for approximately 9% of total emissions (2,037 tCO2e in SBTi base year 2021 (scope 1 = 15,064 and scope 2 = 6,972). Stahl will start to collect primary energy data for large non-manufacturing locations and aims to include this in Scope 1 and 2 reporting for FY2023.

As per our target submission to SBTi, we have estimated direct CO2 emissions from bioenergy, which are considered out of scope.

Renewable energy

The proportion of renewable energy (42%) within Stahl’s overall energy mix (% of total energy consumption) increased by 4% in 2022 (versus 38% in 2021), thanks to continued investment in solar panels and the ongoing transition to renewable electricity.

In Europe, 100% of our manufacturing sites are purchasing renewable electricity. Outside Europe, our sites in Brazil and Singapore purchase 100% renewable electricity.

Managing indirect emissions from our value chain (Scope 3)

The Greenhouse Gas Protocol is the most widely used international framework for carbon accounting. It divides greenhouse gas emissions into three “scopes”. Scope 1 covers direct emissions from owned or directly controlled sources (e.g., factories and vehicles). Scope 2 covers indirect emissions from the generation of purchased electricity, steam, heating, and cooling consumed by the reporting company. Scope 3 includes all indirect emissions that occur within a company’s value chain, both upstream and downstream.

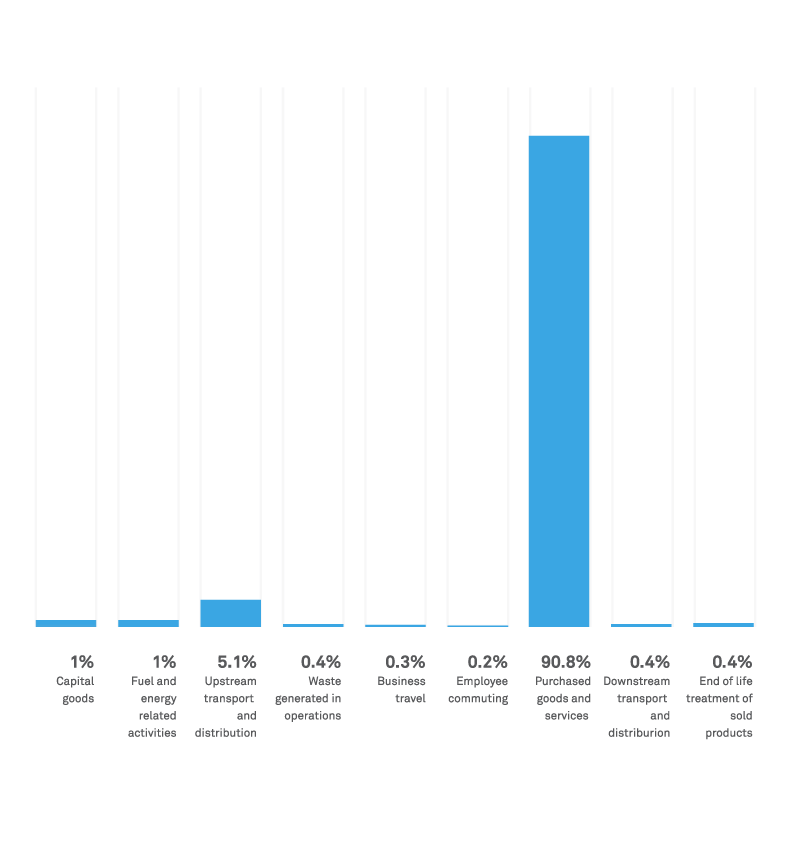

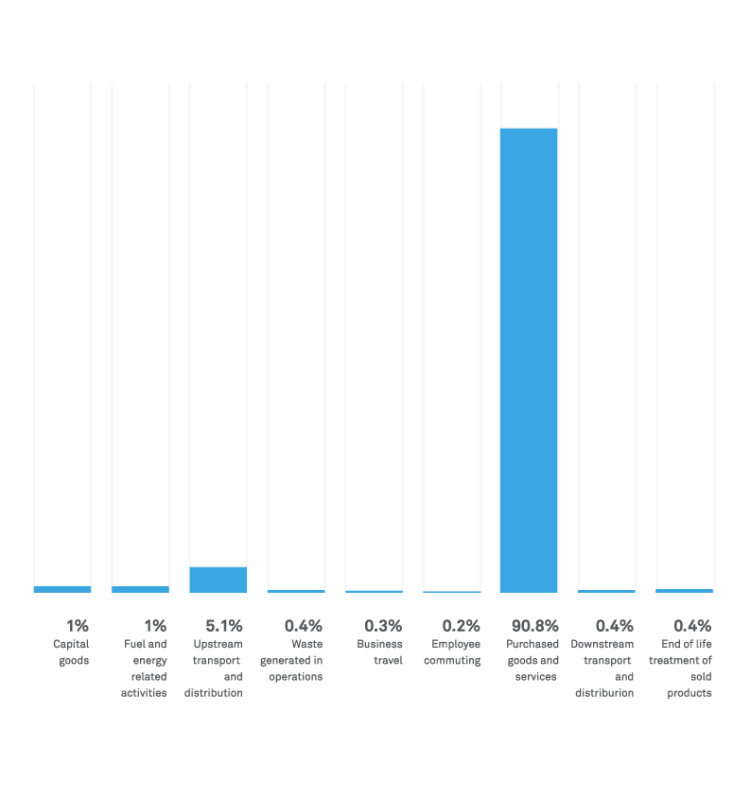

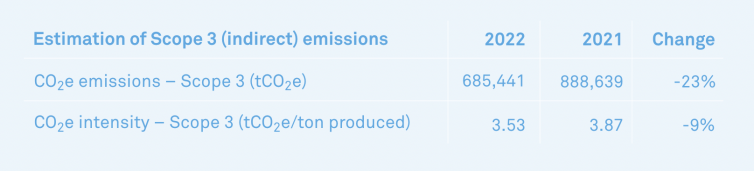

Supported by an external partner, in 2022 Stahl improved the process for calculating its Scope 3 indirect emissions, which account for over 90% of the company's total carbon footprint (Scopes 1, 2, and 3). This has enabled us to submit our first Scope 3 emissions reduction target, in line with the latest SBTi guidelines. We aim to reduce our Scope 3 upstream emissions by at least 25% over the next 10 years (2021 base year vs. 2030 target) and our Scope 1 and 2 emissions by 42% over the same period.

In 2022, Stahl’s largest Scope 3 category was Purchased goods and services (category 1), which includes everything the company sources from its suppliers. The decrease in Scope 3 emissions in 2022 (-23% compared with 2021) is mainly due to a reduction in purchased goods and services. Further improvement of LCA data quality and the sourcing of raw materials with lower carbon footprints were also contributing factors. Our Scope 3 emissions are expected to increase in 2023, following Stahl’s acquisition of Industrial Solutions Group (ISG), a unit of the ICP Group, in March 2023.

Improving calculations and reporting

In 2022, Stahl reviewed and reassessed all 15 GHG Scope 3 emissions categories with the help of an external consultant (not all categories are relevant or material). This provided a very detailed and accurate understanding of how our Scope 3 emissions are generated and was the foundation for setting our Scope 3 emissions reduction target (see above).

Watch our video below to learn more about Stahl’s efforts to reduce our Scope 3 GHG emissions.

“Aligning our emissions reduction targets with the Paris Agreement goals, and securing validation from the Science Based Targets initiative, is an ambitious target that will require continuous technological advances throughout the value chain. We are already working closely with our upstream partners to reach the 10-year milestone, and we will report on our progress in future ESG reports.”

Maarten Heijbroek, CEO of Stahl

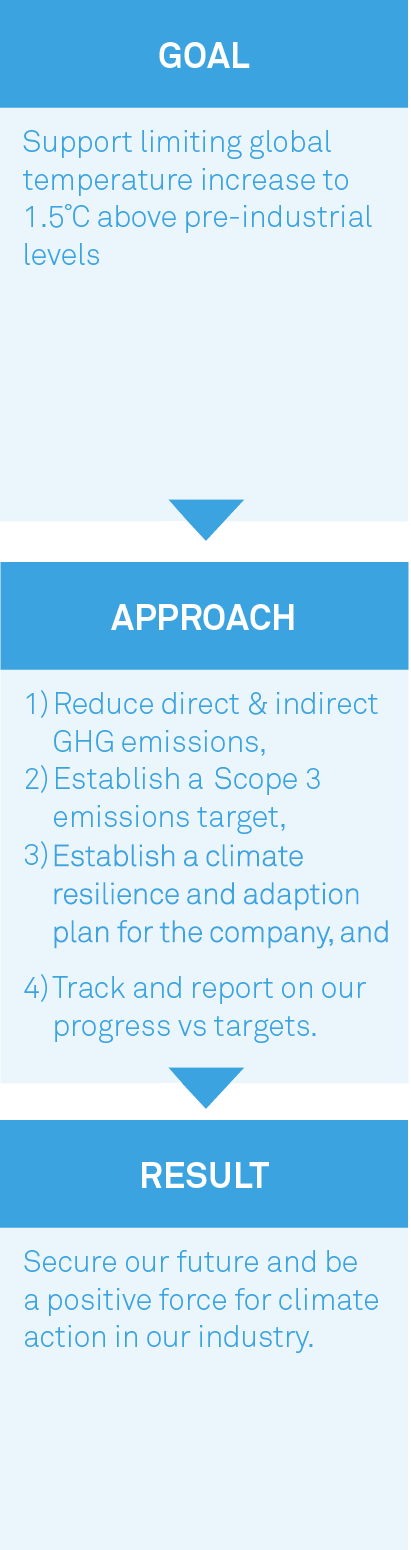

Climate change threatens to have a significant impact on our business over the coming decades. We also recognize our own contribution to this critical issue, either directly through our production processes or indirectly through our wider value chain activities. By integrating our climate resilience plans into our core strategy, we believe we can secure our future and be a positive force for climate action in our industry. The Stahl Climate Resilience & Adaption Plan sets out our approach to climate risk mitigation, including our ambitious targets and how we plan to achieve them.

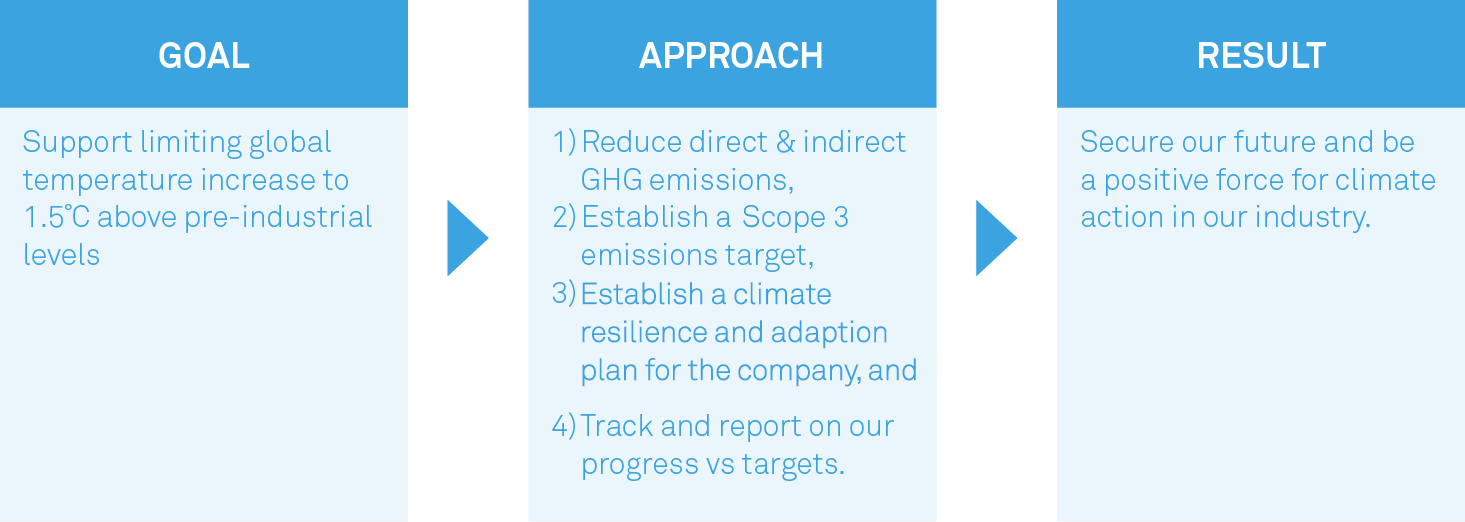

Tackling climate change is the main focus of our environmental stewardship efforts, and is closely linked to two of Stahl’s strategic focus areas: sustainable development and renewable feedstocks. We aim to support worldwide efforts to limit global temperature increase to 1.5˚C above pre-industrial levels, by reducing our own impact on the environment while also working with the wider chemicals value chain to help reduce its overall footprint.

Stahl’s climate targets

Reduce Scope 1 and Scope 2 GHG emissions by 42% over the coming 10 years, compared with the base year (2021).

Reduce Scope 3 upstream emissions by at least 25% over the coming 10 years, compared with the base year (2021).

In 2022, Stahl established 10-year GHG reduction targets that were submitted to the SBTi. These targets are aligned with the net-zero 2050 goals established in the 2015 Paris Climate Agreement.

Our targets:

In 2022, Stahl established dedicated raw material working groups to support the introduction of low-carbon solutions into our material mix as they become available, facilitating the transition to alternative materials with a lower impact. Read more about this initiative in the Governance chapter of this report.

Climate Resilience & Adaption Plan

Transition risks – including policy changes (carbon tax, fossil tax), reputational impacts, and shifts in market preferences, norms, and technologies that are linked to the transition toward a low-carbon economy.

Physical risks – for example, the possible impact of more extreme weather events on Stahl’s manufacturing locations and strategic Centers of Excellence.

The company is building climate resilience into its strategy and operations through continuous dialogue with senior leadership, and by communicating our efforts more broadly within the company. In 2022, we built a climate change matrix to assess climate-related risks based on different scenarios, and calculate their potential financial impact.

Stahl’s Climate Resilience & Adaptation plan ensures that we take action on climate risks and adapt to the impacts of climate change. The plan is structured around the following two categories of risk:

Back

to top

Back to overview

Estimation of Scope 3 (indirect) emissions

Change

2021

2022

CO2e intensity – Scope 3 (tCO2e/ton produced)

CO2e emissions – Scope 3 (tCO2e)

-9%

3.92

3.53

-23.7%

898.888

685,441

Data verified and validated by Deloitte

For each Scope 3 category, total GHG emissions (CO2, CH4, N2O, HFCs, PFCs, and SF6) are reported in metric tons of CO2 equivalent (CO2e), excluding biogenic CO2 emissions and independent of any GHG trades, such as purchases, sales, or transfers of offsets or allowances.

“Aligning our emissions reduction targets with the Paris Agreement goals, and securing validation from the Science Based Targets initiative, is an ambitious target that will require continuous technological advances throughout the value chain. We are already working closely with our upstream partners to reach the 10-year milestone, and we will report on our progress in future ESG reports.”

Maarten Heijbroek, CEO of Stahl

• Replace fossil-based raw materials with lower-carbon alternatives, like renewable =. (e.g., biobased and recycled) feedstocks.

• Ensure that all new product development uses available low-impact raw materials.

• Establish raw material working groups, per material or per category, in which low-carbon alternatives are introduced to replace higher-carbon solutions.

• Measure indirect raw material C02 emissions based on LCA data from suppliers and the ecoinvent/SimaPro database.

• Focus on the top raw material categories, and top individual products, according to \ their GHG impact (i.e., purchased volume x emission factor).

How we plan to get there

Using less energy (Scopes 1 and 2) overall and using energy from renewable sources are both key to achieving our emissions reduction targets. We plan to install more self-generating electricity (solar power) at selected manufacturing sites, and we are continuously investing in energy-saving equipment.

To reduce our Scope 3 (indirect) emissions, we plan to do the following:

In 2022, Stahl established dedicated raw material working groups to support the introduction of low-carbon solutions into our material mix as they become available, facilitating the transition to alternative materials with a lower impact. Read more about this initiative in the Governance chapter of this report.

Climate Resilience & Adaption Plan

Transition risks – including policy changes (carbon tax, fossil tax), reputational impacts, and shifts in market preferences, norms, and technologies that are linked to the transition toward a low-carbon economy.

Physical risks – for example, the possible impact of more extreme weather events on Stahl’s manufacturing locations and strategic Centers of Excellence.

The company is building climate resilience into its strategy and operations through continuous dialogue with senior leadership, and by communicating our efforts more broadly within the company. In 2022, we built a climate change matrix to assess climate-related risks based on different scenarios, and calculate their potential financial impact.

Stahl’s Climate Resilience & Adaptation plan ensures that we take action on climate risks and adapt to the impacts of climate change. The plan is structured around the following two categories of risk:

For each Scope 3 category, total GHG emissions (CO2, CH4, N2O, HFCs, PFCs, and SF6) are reported in metric tons of CO2 equivalent (CO2e), excluding biogenic CO2 emissions and independent of any GHG trades, such as purchases, sales, or transfers of offsets or allowances.

In 2022, Stahl’s largest Scope 3 category was Purchased goods and services (category 1), which includes everything the company sources from its suppliers. The decrease in Scope 3 emissions in 2022 (-23% compared with 2021) is mainly due to a reduction in purchased goods and services. Further improvement of LCA data quality and the sourcing of raw materials with lower carbon footprints were also contributing factors. Our Scope 3 emissions are expected to increase in 2023, following Stahl’s acquisition of Industrial Solutions Group (ISG), a unit of the ICP Group, in March 2023.

Improving calculations

and reporting

In 2022, Stahl reviewed and reassessed all 15 GHG Scope 3 emissions categories with the help of an external consultant (not all categories are relevant or material). This provided a very detailed and accurate understanding of how our Scope 3 emissions are generated and was the foundation for setting our Scope 3 emissions reduction target (see above).

Watch our video below to learn more about Stahl’s efforts to reduce our Scope 3 GHG emissions.

Managing indirect emissions from our value chain (Scope 3)

The Greenhouse Gas Protocol is the most widely used international framework for carbon accounting. It divides greenhouse gas emissions into three “scopes”. Scope 1 covers direct emissions from owned or directly controlled sources (e.g., factories and vehicles). Scope 2 covers indirect emissions from the generation of purchased electricity, steam, heating, and cooling consumed by the reporting company. Scope 3 includes all indirect emissions that occur within a company’s value chain, both upstream and downstream.

Supported by an external partner, in 2022 Stahl improved the process for calculating its Scope 3 indirect emissions, which account for over 90% of the company's total carbon footprint (Scopes 1, 2, and 3). This has enabled us to submit our first Scope 3 emissions reduction target, in line with the latest SBTi guidelines. We aim to reduce our Scope 3 upstream emissions by at least 25% over the next 10 years (2021 base year vs. 2030 target) and our Scope 1 and 2 emissions by 42% over the same period.

Direct CO2 removals

from bioenergy (S1)

4,575

CO2 removals due to the biological source's

sequestration during its life

CO2 emissions emitted from the combustion of the biological source for bioenergy PLUS the land use change emissions as a result

4,611

Direct CO2 emissions

from bioenergy (S1)

Notes

2022 Emissions (tCO2e)

Out of scope (CO2 only)

Renewable energy

The proportion of renewable energy (42%) within Stahl’s overall energy mix (% of total energy consumption) increased by 4% in 2022 (versus 38% in 2021), thanks to continued investment in solar panels and the ongoing transition to renewable electricity.

In Europe, 100% of our manufacturing sites are purchasing renewable electricity. Outside Europe, our sites in Brazil and Singapore purchase 100% renewable electricity.

ESG roadmap to 2030

2030 goal: 6 sites using on-site renewable sources

(minimum 20% of total energy usage)

2022 progress (on target): solar panels installed at 3 sites

Back

to top

Energy and emissions

Stahl’s energy consumption comes primarily from its production processes (whereby chemical reactions are used to produce specialty products). We continue to invest in cleaner and renewable energy sources and to further reduce our energy consumption. The largest potential improvement area for GHG emission reduction is linked to the purchase of raw materials. In 2022, Stahl’s GHG emission reduction targets were submitted to the Science Based Targets initiative (SBTi). Science-based targets provide a clearly defined pathway for companies to reduce GHG emissions, helping prevent the worst impacts of climate change to enable future-proof business growth. Targets are considered to be science-based if they are in line with the scientific consensus on the level of action required to meet the goals of the Paris Agreement: limiting global warming to 1.5°C above pre-industrial levels.

Our SBTi target (pending validation) is to reduce absolute Scope 1 and Scope 2 GHG emissions by 42% over the next ten years (2030 target year versus 2021 base year). We will do this by reducing our energy consumption and continuing our transition to renewable energy sources. Stahl’s European sites already purchase 100% of their electricity from renewable sources, and we have installed solar panels at 3 sites: Brazil (2018), India (2022), and Mexico (2022).

Scope 1 absolute emissions in 2022 dropped by 15% (11,852 tCO2e versus 13,898 tCO2e in 2021), mainly because of energy efficiencies and lower production volumes.

Scope 2 absolute emissions dropped by 24% (4,617 tCO2e versus 6,101 tCO2e in 2021), mainly as a result of our investment in solar panels.

SBTi validation is pending (final stage)

As we build on this momentum, we have a key milestone firmly in our sights. 2030 will mark the 100th anniversary of Stahl. It is also the end point of our ESG Roadmap to 2030, by which time we expect to have achieved our mid-term ESG targets. More importantly, by the end of this decade, I expect to see the wider chemicals industry making more significant progress toward de-fossilization than in the previous 30 years, with Stahl acting as a driving force in our markets.

Collaboration will be key. By working together – as one value chain – I believe the chemical industry can be part of the solution for mitigating climate change, reversing the global warming trend, and progressively reducing biodiversity loss.

This section of our 2022 ESG Report follows our climate change ambitions and our recent efforts to reduce the environmental impact of Stahl and its value chain partners.

Achieving our GHG targets will be challenging, since many of the activities in the value chain take place upstream, beyond our direct influence. However, we have built the foundations needed to help us get there. As a founding member of the Renewable Carbon Initiative (RCI), we play a key role in supporting the de-fossilization of the chemicals value chain and its transition to renewable feedstocks. We are investing significant resources in measuring the footprint of our raw materials and products using Life Cycle Assessment (LCA) methodology. We are also working to secure relevant supply chain certifications, such as RedCert² and ISCC PLUS.

Reducing our impact, together

Addressing climate change is the number one priority for all stakeholders across the chemicals sector. The industry is estimated to be responsible for roughly 7% of global GHG emissions, and its relative contribution is likely to increase as the energy sector steadily decarbonizes.

Stahl has achieved significant reductions in GHG emissions since 2015 (37% absolute emission reductions in 2020 in Scope 1 and 2) when the Paris Agreement was signed. In 2022, we submitted an emissions reduction target to the Science Based Targets initiative (SBTi).

Tackling climate change is the main focus of our environmental stewardship efforts, and is closely linked to two of Stahl’s strategic focus areas: sustainable development and renewable feedstocks. We aim to support worldwide efforts to limit global temperature increase to 1.5˚C above pre-industrial levels, by reducing our own impact on the environment while also working with the wider chemicals value chain to help reduce its overall footprint.

Stahl’s climate targets

Reduce Scope 1 and Scope 2 GHG emissions by 42% over the coming 10 years, compared with the base year (2021).

Reduce Scope 3 upstream emissions by at least 25% over the coming 10 years, compared with the base year (2021).

In 2022, Stahl established 10-year GHG reduction targets that were submitted to the SBTi. These targets are aligned with the net-zero 2050 goals established in the 2015 Paris Climate Agreement.

Our targets:

Climate change threatens to have a significant impact on our business over the coming decades. We also recognize our own contribution to this critical issue, either directly through our production processes or indirectly through our wider value chain activities. By integrating our climate resilience plans into our core strategy, we believe we can secure our future and be a positive force for climate action in our industry. The Stahl Climate Resilience & Adaption Plan sets out our approach to climate risk mitigation, including our ambitious targets and how we plan to achieve them.